Screen printing may seem intimidating, but it’s actually a fun and creative way to personalize your leather products. Whether you’re looking to add a design to a leather jacket, a purse, or even a pair of earrings, screen printing can give your leather items a unique touch.

Screen printing on leather involves using a stencil to transfer ink onto the leather surface. The process is similar to screen printing on other materials, but there are a few key differences to keep in mind. For example, leather is a porous material, which means that the ink may spread more than it would on a non-porous surface.

Additionally, leather can be sensitive to heat, so it’s important to use the right type of ink and curing method to avoid damaging the leather. With a little bit of practice and some helpful tips, you can create beautiful screen-printed designs on leather that will last for years to come. Keep reading.

Key Points:

- Screen printing on leather is a versatile and cost-effective method for creating custom designs on leather items.

- Specialized tools and materials such as a screen, ink, and a squeegee are required for screen printing on leather.

- High-quality ink designed specifically for use on leather should be used to ensure proper adhesion and durability.

- Proper alignment of the screen and applying sufficient pressure during printing are important for successful results.

- Choosing high-quality leather, creating a stencil, and using the right type of ink are crucial for achieving professional-looking prints.

- Cleaning the screen thoroughly after each use and following manufacturer instructions for each product will ensure longevity.

- Screen printing on leather can be done on various items like jackets, handbags, wallets, labels, and even earrings, but considerations must be made based on the specific item and its properties.

Understanding Screen Printing

Screen printing is a popular printing technique used in the textile industry. It involves the use of a stencil, a mesh screen, and ink to create a print on a fabric or material. Unlike digital printing, which is the process of printing an image directly onto a material, screen printing involves using a screen to transfer an image onto a surface, making it a more versatile and cost-effective method.

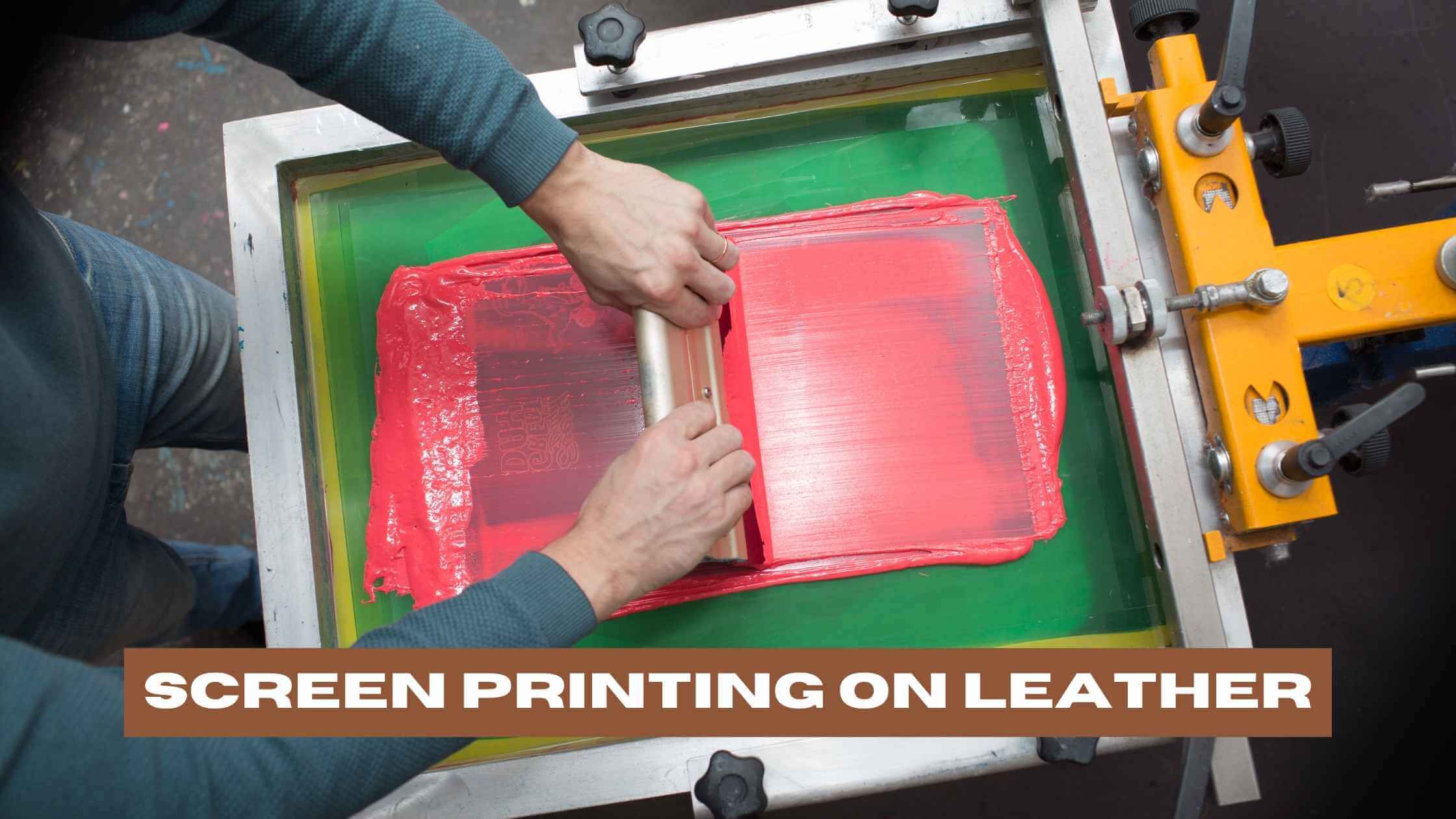

To screen print on leather, you will need a few specialized tools and materials, including a screen, ink, and a squeegee. The process is similar to screen printing on other materials, but there are a few key differences to keep in mind. For example, when printing on leather, you will need to use a thicker ink to ensure that it adheres properly to the material.

Using a screen to print on leather allows you to create custom designs and patterns that can be used for a variety of projects, from clothing and accessories to home decor. You can use a single screen to create multiple prints, making it a cost-effective option for small businesses and DIY enthusiasts.

When it comes to screen printing on leather, there are a few tips and tricks to keep in mind. For example, it’s important to use high-quality ink that is designed specifically for use on leather. You’ll also want to make sure that your screen is properly aligned and that you apply enough pressure when printing to ensure that the ink adheres properly.

Materials Required for Screen Printing on Leather

To get started with screen printing on leather, you will need a variety of materials. These include:

- Leather: The type of leather you use will depend on the item you are printing on. It is important to choose high-quality leather that is smooth and even in texture.

- Stencil: A stencil is used to create the design you want to print. You can create stencils using a variety of materials, including emulsion, paint, or ink.

- Ink: Choose an ink that is specifically designed for use on leather. Water-based and solvent-based inks are both commercially available.

- Squeegee: This tool is used to spread the ink across the screen and onto the leather.

- Mesh: The mesh is used to hold the stencil in place and to allow the ink to pass through onto the leather.

- Platen: The platen is the flat surface on which the leather is placed for printing.

- Heat gun: A heat gun can be used to dry the ink more quickly.

- Coating: A coating or lacquer can be applied to the leather after printing to protect the design.

When selecting your materials, it is important to choose high-quality products that are designed specifically for screen printing on leather. This will ensure that your finished product looks professional and lasts for a long time.

To get the best results, make sure that you follow the manufacturer’s instructions for each product you use. This will ensure that you use the correct amount of ink or dye and that you apply it evenly to the leather.

Additionally, it is important to rinse the leather thoroughly after printing to remove any excess ink or dye. You may also want to use an adhesive or masking tape to hold the leather in place during printing.

The Screen Printing Process

Screen printing on leather is a fun and easy way to add a personal touch to your leather items. Here’s a step-by-step guide on how to screen print on leather:

- Prepare the screen: Choose a screen with a tighter mesh count, such as 230, to ensure a clean print. Tighten the mesh to around 25 newtons to prevent ink from bleeding through. Apply a scoop coater to the screen to create a thin, even layer of emulsion.

- Print the design: Print the design onto the emulsion using an inkjet printer. Make sure to print the design in reverse so that it appears correctly when printed onto the leather.

- Dry the ink: Allow the ink to dry completely before printing. Air drying is recommended, but you may add a heat source to speed up the drying process.

- Set up the hinge: Place the leather item onto the printing surface, and secure it in place using a hinge. This will keep the leather item in place during the printing process.

- Flood the screen: Apply a small amount of water-based ink onto the screen. Use a squeegee to spread the ink evenly across the design.

- Pull the screen: Pull the screen downwards towards the leather item. Apply pressure to ensure that the ink transfers onto the leather.

- Repeat the process: If you are printing a multi-color design, repeat the process with different layers of ink and a fine mesh screen.

- Bond the ink: Once the ink has dried, use a heat source to bond the ink to the leather. High temps are recommended for a stronger bond.

Screen Printing on Different Leather Items

Screen printing on leather is a popular way to add a personal touch to different leather items. You can use this technique to print on leather jackets, handbags, wallets, labels, and even earrings. The process is straightforward, and you can achieve excellent results with a little practice.

When screen printing on a leather jacket, it’s essential to choose the right type of leather. Some leathers are more porous than others, and this can affect the quality of the print. You should also consider the color of the leather and choose a contrasting ink color for the print to stand out. You can use a stencil to create the design, and make sure to apply even pressure when printing.

For handbags and wallets, you can use the same technique as for a leather jacket. However, it’s important to consider the size of the item and adjust the design accordingly. You can also experiment with different ink colors and textures to create a unique look.

Labels are another great item to screen print on. You can use this technique to create custom labels for your leather items, such as a logo or brand name. It’s important to choose a durable ink that won’t fade or crack over time.

Earrings are a fun and unique item to screen print on. You can use this technique to create custom designs and patterns on leather earrings. It’s important to choose a thin and flexible leather, such as faux leather, to ensure the earrings are comfortable to wear.

When screen printing on leather, it’s important to use the right tools and materials. You’ll need a screen printing frame, ink, squeegee, and stencil. It’s also important to choose the right type of ink for the leather you’re printing on.

Tips and Tricks for Successful Screen Printing on Leather

If you are new to screen printing on leather, there are a few things you need to know to ensure a successful outcome. Here are some tips and tricks to help you get started:

- Use a thin layer of ink: Unlike thicker acrylic paints used for other types of printing, water-based ink for screen printing is very thin and may bleed through the screen if applied too thickly. Apply a thin layer of ink to your screen to prevent this from happening.

- Let the emulsion dry completely: Before you start printing, make sure that the emulsion on your screen is completely dry. If it is not, the ink may not adhere properly to the leather.

- Use solvent-based ink: While water-based ink is suitable for some types of fabric, it is not always the best choice for leather. Solvent-based ink is more durable and will last longer on leather jackets and other leather items.

- Test your design on a scrap piece of leather: Before you start printing on your final project, it is a good idea to test your design on a scrap piece of leather. This will give you an idea of how the ink will look on the leather and help you make any necessary adjustments.

- Use a screen with a high mesh count: A screen with a high mesh count will give you a sharper and more detailed print. A mesh count of 110-160 is ideal for printing on leather.

- Clean your screen thoroughly after each use: To ensure that your screen lasts as long as possible, it is important to clean it thoroughly after each use. Use a screen cleaner and a soft brush to remove any ink or emulsion residue.

FAQ: Screen Printing on Leather

What is screen printing on leather?

Screen printing on leather is a technique used to transfer ink onto leather surfaces using a screen with a stencil.

How is screen printing on leather different from other printing methods?

Screen printing on leather is different from other printing methods because it allows for precise and detailed designs on leather surfaces.

What materials do I need for screen printing on leather?

To screen print on leather, you will need a leather jacket or any other leather item, screen printing equipment, screen printing ink, and a squeegee.

Can I use regular acrylic paints for screen printing on leather?

Regular acrylic paints may not be suitable for screen printing on leather. It is recommended to use specific leather paints or inks that are designed for this purpose.

How do I prepare the leather surface for screen printing?

Before screen printing on leather, make sure the surface is clean and free from any dust or oils. You can use a mild cleaner or rubbing alcohol to prepare the leather.

What is the ideal mesh count for screen printing on leather?

The ideal mesh count for screen printing on leather depends on the design and desired outcome. Generally, a higher mesh count (between 150-200) is preferable for detailed designs.

How tight should the screen be for screen printing on leather?

The screen should be tightened to a tension of around 25 newtons for screen printing on leather. This ensures even and consistent ink transfer.

What type of squeegee should I use for screen printing on leather?

It is recommended to use a 70 durometer squeegee for screen printing on leather. This provides the right amount of pressure and flexibility for ink transfer.

Can I screen print on different types of leather?

Yes, you can screen print on various types of leather, including leather used for jackets, handbags, or labels. However, it is advisable to test your screen printing process on a small area first.

Can I use heat transfer for screen printing on leather?

Heat transfer is not typically used for screen printing on leather. Screen printing directly onto the leather surface is the preferred method for lasting and durable prints.