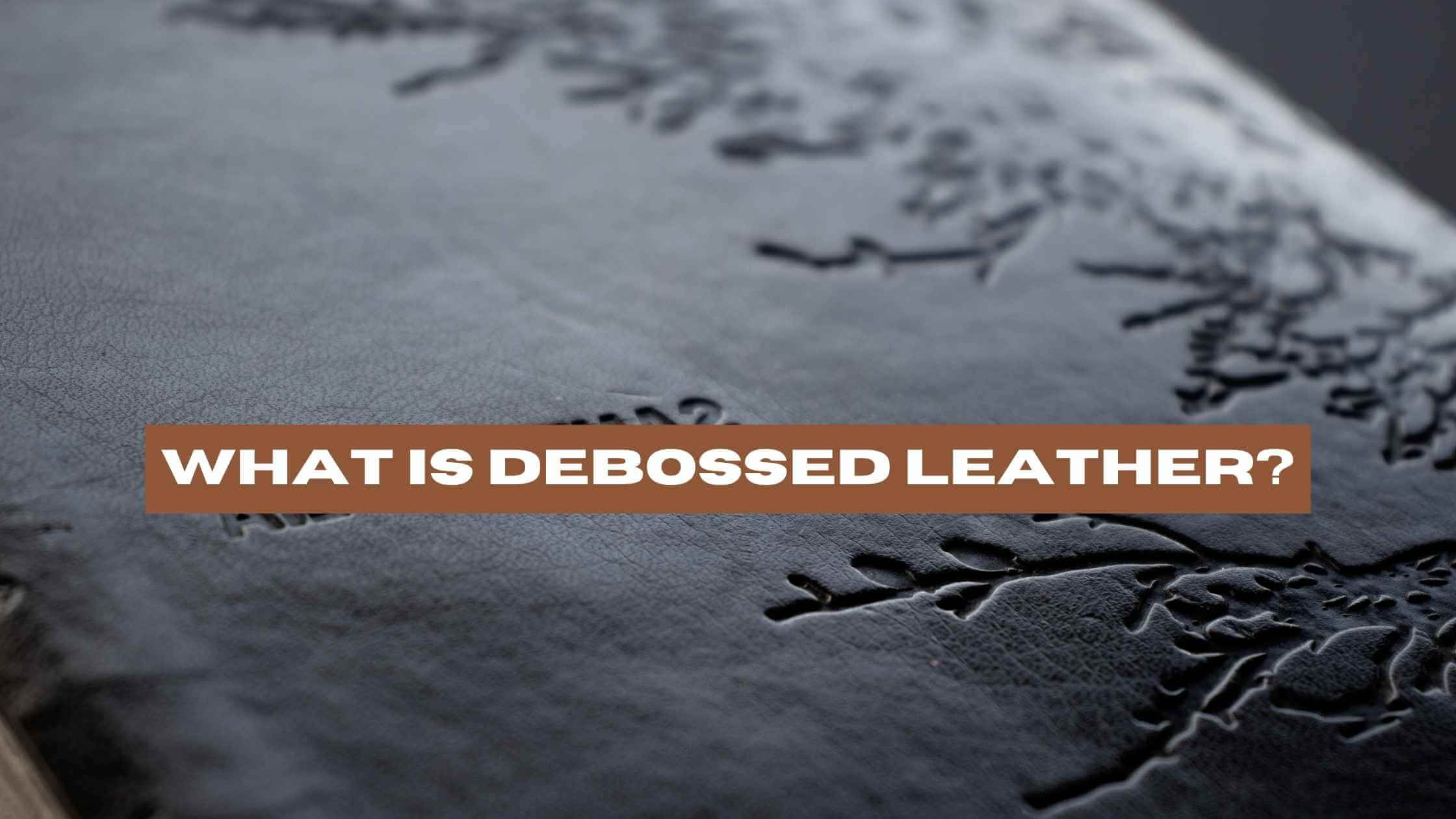

If you’re a fan of leather goods, you’ve probably heard of debossed leather. But what is debossed leather exactly, and how is it made?

Debossed leather is a type of leather that has undergone a process to create an indented impression of a design using heat, pressure, or moisture. This technique results in a unique, permanent design that adds texture and sophistication to various leather products. Debossing can be used to create a wide range of designs, from simple patterns to intricate logos and lettering.

Main Points:

- Debossed leather is a type of leather that has been compressed to create an indented design using heat, pressure, or moisture.

- Debossing can be done on any type of leather and is commonly used for various leather goods, including wallets, bags, and belts.

- The process of debossing leather involves placing a metal plate with the desired design onto the leather surface and pressing it with force to create the indented design.

- Debossed leather designs are permanent and won’t fade or wear off over time, making them a popular choice for high-end leather goods.

- There are different types of debossing, including blind embossing, multi-level embossing, registered embossing, combination embossing, pastelling embossing, glazing embossing, and scorching embossing.

- The materials suitable for debossing include leather, paper, metal, foil, plastic, cardstock, fabric, and vinyl.

- Debossing allows for personalized and artistic designs, making it a great way to add sophistication and uniqueness to leather products like wallets, luggage tags, business cards, portfolios, journals, t-shirts, stationery, and more.

The Debossing Process

When it comes to creating a debossed leather product, the process involves compressing the leather to leave a recessed impression. This can be done using moisture, heat, or the excessive force of an industrial press. Below are the steps involved in the debossing process:

- Design Preparation: The first step is to prepare the design that will be debossed onto the leather. This can be a logo, name, or any other design. The design is then transferred onto a metal plate, which will be used to create the debossed impression.

- Plate Heating: The metal plate is then heated to a temperature of about 212°F (100°C). This is done to ensure that the plate is hot enough to create the impression on the leather.

- Leather Placement: The leather is then placed onto the press, and the metal plate is positioned on top of it.

- Pressing: The press is then activated, and the metal plate is pressed onto the leather with a significant amount of force. This pressure, combined with the heat from the plate, creates the debossed impression on the leather.

- Finishing: Once the impression is created, the leather is removed from the press, and any excess material is trimmed away. The finished product is then inspected to ensure that the debossed impression is clean and well-defined.

It’s worth noting that the debossing process is different from embossing. While debossing creates a recessed impression, embossing creates a raised impression. Additionally, debossing works best on leather, paper, and vinyl materials.

When it comes to creating a metal plate for debossing, there are several options available. The most common materials used for plates are brass, magnesium, and steel. The type of material used depends on the specific requirements of the project, such as the power and strength needed to create the desired impression.

Types of Debossing

When it comes to debossed leather, there are several types of debossing that you can choose from. Each type of debossing has its own unique characteristics, and understanding these differences can help you choose the right type of debossing for your project.

Blind Embossing

Blind embossing is the most basic type of debossing, and it involves creating a recessed impression in the leather without adding any color or foil. This type of debossing is great for creating a subtle, understated look.

Multi-Level Embossing

Multi-level embossing is a more complex type of debossing that involves creating multiple levels of depth in the impression. This type of debossing can create a highly textured look and feel, and it’s great for adding depth and dimension to your design.

Registered Embossing

Registered embossing involves aligning the debossed impression with a printed design on the leather. This type of debossing is great for creating a seamless, integrated look between the debossed impression and the printed design.

Combination Embossing

Combination embossing involves combining two or more types of debossing techniques to create a unique look. For example, you could combine blind embossing with registered embossing to create a debossed impression that’s aligned with a printed design but also has a subtle, understated look.

Pastelling Embossing

Pastelling embossing involves adding a layer of color to the debossed impression. This type of debossing is great for creating a bold, colorful look, and it can be used to create a wide range of effects.

Glazing Embossing

Glazing embossing involves applying a layer of wax or polish to the debossed impression to create a glossy, shiny look. This type of debossing is great for creating a high-end, luxurious look and feel.

Scorching Embossing

Scorching embossing involves using heat to create a burned or scorched look in the leather. This type of debossing is great for creating a rustic, vintage look, and it can be used to create a wide range of effects.

Other Materials Suitable for Debossing

When it comes to debossing, there are many materials that can be used to achieve a beautiful and functional impression. Here are some of the most common materials suitable for debossing:

Leather

Leather is a popular material for debossing because of its durability and classic look. It is commonly used for items such as wallets, journals, and portfolios. Debossing on leather creates a subtle yet elegant impression that adds a touch of sophistication to any item.

Paper

Paper is one of the most common materials used for debossing. It is a versatile material that can be used for a variety of projects, such as invitations, business cards, and stationery. Debossing on paper creates a tactile impression that adds depth and texture to the design.

Metal

Metal is a durable material that can be used for a variety of applications, such as jewelry, keychains, and belt buckles. Debossing on metal creates a permanent impression that is both functional and aesthetic.

Foil

Foil is a popular material for debossing because of its reflective properties. It is commonly used for items such as business cards, invitations, and packaging. Debossing on foil creates a striking impression that adds a touch of luxury to any design.

Plastic

Plastic is a versatile material that can be used for a variety of applications, such as ID cards, luggage tags, and promotional items. Debossing on plastic creates a durable impression that is both functional and aesthetically pleasing.

Cardstock

Cardstock is a heavy paper that is commonly used for invitations, greeting cards, and other stationery items. Debossing on cardstock creates a tactile impression that adds depth and texture to the design.

Fabric

Fabric is a popular material for debossing because of its versatility and durability. It is commonly used for items such as bags, hats, and clothing. Debossing on fabric creates a subtle yet elegant impression that adds a touch of sophistication to any item.

Vinyl

Vinyl is a flexible material that can be used for a variety of applications, such as decals, signage, and promotional items. Debossing on vinyl creates a durable impression that is both functional and aesthetically pleasing.

Debossed Leather Products

If you’re looking for a way to add a touch of sophistication to your leather products, debossing may be just what you need. Debossing is a process that involves pressing a design into the surface of the leather, creating an indented impression that can be both aesthetic and functional.

Debossed leather products can be found in a variety of forms, from wallets and luggage tags to business cards and promotional items. Here are some examples of debossed leather products and how they can be used:

- Wallets: Debossing can be used to add a personal touch to a leather wallet, such as a monogram or a favorite quote.

- Luggage tags: A debossed luggage tag can help you spot your bag on the carousel and add a touch of style to your travels.

- Business cards: Debossing your business logo or contact information onto a leather card can make a lasting impression on potential clients.

- Promotional products: Debossed leather items can make great promotional products, such as keychains or coasters, that customers will use and appreciate.

- Portfolios: A debossed leather portfolio can add a touch of professionalism to your business meetings or interviews.

- Journals: A debossed leather journal can make a great gift for a writer or artist, and the impression can add texture to the cover.

- T-shirts: Debossing can be used on leather patches that are then applied to t-shirts, creating a unique and stylish look.

- Stationery: Debossing can be used on leather-bound notebooks or journals, adding a touch of elegance to your writing.

When choosing a debossed leather product, consider the size and placement of the design, as well as the color and type of leather. Debossing can be done on any kind of leather, but different types may yield different results. Additionally, be sure to choose a reputable company or craftsman who can provide high-quality debossing services.

Art and Design in Debossing

Debossing is not just a functional technique, but it can also be an art form. The recessed impressions left on leather can be used to create beautiful designs and patterns that add an aesthetic appeal to leather goods.

When it comes to art and design in debossing, there are endless possibilities. You can use custom designs, logos, graphics, patterns, words, and more to create unique and personalized impressions on leather. Whether you want to add a subtle touch of elegance or make a bold statement, debossing can help you achieve your desired look.

One of the most popular uses of debossing in art and design is for logos. Businesses often use debossing to imprint their logos onto leather products, creating a professional and sophisticated look. Additionally, debossing can be used to add texture and depth to designs, making them stand out even more.

Debossing can also be used to create custom designs, such as monograms or patterns. By etching a custom design onto leather, you can create a one-of-a-kind piece that truly reflects your personal style.

When it comes to color, debossing is typically done in black or a similar dark color to create a subtle contrast with the leather. However, you can also fill in the recessed areas with ink or foil stamping to add a pop of color and make the design even more eye-catching.

Custom Debossing

Custom debossing is a popular decoration method used to add a unique touch to leather products such as bags, journals, and wallets. It involves the process of compressing leather to leave a recessed impression using moisture, heat, or the excessive force of an industrial press. This method is perfect for adding custom logos, designs, and monograms to leather products.

When you opt for custom debossing, you have the freedom to choose the design, font, and size of the impression you want to create. The debossing process is done using heated brass dies, which are then hand-pressed down into the leather, creating a stamped effect. The result is a clean and elegant look that gives your product a professional finish.

Custom debossing is one of the most popular methods of customizing leather products. It is durable and long-lasting, ensuring that your design will remain visible for years to come. The 3D embedded design that is achieved through debossing gives your product both dimensional depth and texture. It can also be used in conjunction with printing or foil stamping to create a unique and eye-catching design.

When you choose custom debossing, you can be sure that your product will stand out from the rest. It is a great way to add a personal touch to your leather products, making them unique and special. Whether you are looking to add a monogram to a leather wallet or a logo to a leather bag, custom debossing is the perfect way to do it.

Cost of Debossing

When it comes to debossing leather, the cost can vary depending on several factors. Here are some things to consider when estimating the cost of debossing:

Quantity

The quantity of items you want to have debossed will affect the overall cost. Generally, the more items you have, the lower the cost per item will be. For example, if you want to have 10 leather journals debossed, the cost per journal will be higher than if you wanted to have 100 journals debossed.

Size

The size of the debossed area will also affect the cost. The larger the area, the more material and time will be required to complete the debossing.

Complexity

The complexity of the design will also play a role in the cost. Intricate designs with fine details will require more time and effort to deboss, which will increase the cost.

Type of Leather

The type of leather you choose will also affect the cost. Some leathers are more expensive than others, and some are more difficult to deboss than others. For example, full-grain leather is more expensive than top-grain leather, but it is also easier to deboss.

Customization

If you want to have a custom design created specifically for your debossed leather item, this will also increase the cost. The cost of design work will vary depending on the complexity of the design and the expertise of the designer.

Debossing Equipment

To create a debossed impression on leather, you need specialized equipment. Here are some of the essential tools you’ll need to get started:

1. Debossing Machine

The debossing machine is the most critical piece of equipment you’ll need. It’s a hydraulic press that uses pressure and heat to compress the leather and create the recessed impression. You can choose from manual or automatic debossing machines, depending on your needs and budget.

2. Dies

Dies are metal plates that have a design or logo etched into them. They’re used with the debossing machine to create the impression on the leather. You can have custom dies made with your logo or design, or you can choose from a range of pre-made dies.

3. Heat Source

Heat is a crucial component of the debossing process. You’ll need a heat source to warm up the metal dies before they’re pressed onto the leather. A hot plate or a heat gun can be used for this purpose.

4. Leather

Of course, you’ll need high-quality leather to create your debossed designs. Choose leather that’s thick enough to withstand the pressure of the debossing machine but not too thick that it’s difficult to work with. Full-grain leather is an excellent choice for debossing because it’s durable and has a natural texture that looks great with a debossed impression.

5. Protective Gear

When working with a hydraulic press, it’s essential to wear protective gear to prevent injury. You’ll need gloves to protect your hands and safety glasses to protect your eyes from flying debris.

Debossing vs. Embossing

When it comes to leather personalization, debossing, and embossing are two popular techniques to create a unique and stylish look. While both techniques involve pressing a design onto the leather surface, there are some key differences between them.

Embossing

Embossing involves creating a raised design on the leather surface. This is achieved by using a metal plate with a raised design that is pressed onto the leather. The pressure applied by the plate creates a raised design on the leather surface. Embossing is commonly used to create logos, patterns, and other decorative designs on leather products.

Debossing

Debossing is the opposite of embossing. It involves creating a depressed design on the leather surface. This is achieved by using a metal plate with a depressed design that is pressed onto the leather. The pressure applied by the plate creates a depressed design on the leather surface. Debossing is commonly used to create monograms, initials, and other personalized designs on leather products.

One of the main differences between embossing and debossing is the direction of the pressure applied to the leather surface. In embossing, the pressure is applied from underneath the leather, while in debossing, the pressure is applied from the top of the leather. This results in a raised or depressed design on the leather surface, respectively.

Another difference between the two techniques is the number of dies or plates used. Embossing requires two dies or plates while debossing requires only one die or plate. This makes debossing a more cost-effective option than embossing.

Competition in Debossing Market

When it comes to debossed leather, there is a lot of competition in the market. Many companies offer debossing services for various leather goods, such as portfolios, wallets, and bags.

One of the main factors that differentiate companies in the debossing market is the quality of their work. Some companies use high-quality equipment and materials to ensure that their debossed designs are crisp and long-lasting. Others may use lower-quality equipment, resulting in less defined impressions that may wear off over time.

Another factor that sets companies apart is their ability to create custom designs. Some companies have a wide range of pre-made designs to choose from, while others offer the option to upload your own custom design. It’s important to choose a company that can accommodate your specific needs and preferences.

Pricing is also a crucial factor in the debossing market. Some companies charge a flat rate for their services, while others may charge per letter or per design. It’s important to compare prices and ensure that you are getting a fair deal for the quality of work you are receiving.

Finally, turnaround time can be a deciding factor for some customers. Some companies offer expedited services for an additional fee, while others may take longer to complete orders. It’s important to factor in the time it will take to receive your debossed leather item when choosing a company.

FAQ: What is Debossed Leather?

What is the difference between embossed and debossed leather?

Embossed leather is when a design is raised above the surface of the leather, while debossed leather is when a design is pressed into the surface of the leather. Embossing creates a 3D effect, while debossing creates an indented effect. Both techniques can be used to add a unique design element to leather products.

Why use debossed?

Debossing is a great way to add a subtle yet sophisticated touch to leather products. It can be used to add a logo or design to a variety of leather goods, including wallets, portfolios, and even furniture. Debossing is a durable and long-lasting way to customize leather products.

What is the difference between embossed and debossed tablets?

Embossed tablets have a raised design on the surface of the tablet, while debossed tablets have an indented design. The choice between embossed and debossed tablets often comes down to personal preference. Some people prefer the tactile feel of a raised design, while others prefer the subtlety of an indented design.

How to deboss leather with Cricut Maker?

To deboss leather with Cricut Maker, you will need a debossing tool and a cutting mat. First, create your design in Cricut Design Space. Then, load your leather onto the cutting mat and insert the debossing tool into the machine. Follow the prompts in Cricut Design Space to deboss your design onto the leather.

Where can I find leather debossing near me?

You can find leather debossing services at many local leather shops and specialty printing shops. You can also search online for leather debossing services in your area. Be sure to read reviews and compare prices before choosing a service.